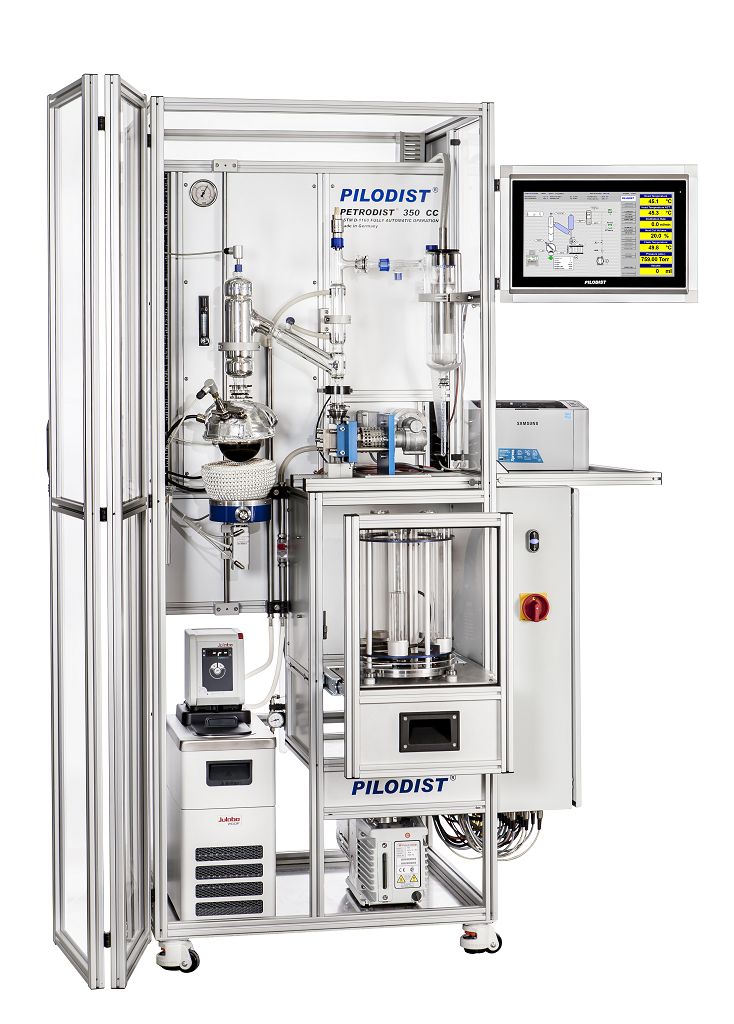

Kirjeldus

- Operate in strict accordance with ASTM D1160 by using 1 single receiver or using a new type of automatic fraction collector with 5 receivers, 200 mL each

- Fraction collector can be operated by volume or by preselected cut temperatures

- Software kit to perform distillation similar ASTM D5236 with dynamic vacuum reduction procedure down to 0,1 Torr

- Flask sizes available 500, 1000, 2000 mL

- Tempered automatic discharge pump for easy drain of even viscous product into open fraction collector

- Receivers can be closed with cap GL 45

- New PILODIST brand touch screen panel control

- Fully automatic reporting and storage of results

- Atmospheric distillation

- Water removal (dehydration) process prior to distillation

- Biodiesel distillation

- LIMS connectivity

The distillation volume is measured automatically in receivers, temperature controlled by an IR-heater. The yield is calculated in percentage to the charge quantity. Distillation report, final data and distillation curve are printed out.

Technical Data

| Available flask sizes | 500 mL |

| Flask charge | 200 mL |

| Operating temperature | Up to 400° C (750° F) |

| Final cut temperature | up to 650° C AET |

| Max ambient temperature | 25° C |

| Fraction collector | 5 calibrated receivers, 200 mL each |

| Operating pressure | vacuum down to 0,1 Torr |

| Mains supply | 208-250 V, 50 Hz (standard)

208-250V, 60 Hz (optional) |