Description

Special Advantages

- Patent Pending Hybrid Evaporator

- High capacity glass condenser

- Precise Vacuum control system

- Vertical design for optimized product flow without hold-up in useless pumping lines

- Hermetically sealed, high vacuum tight, tempered gear pumps for fully continuous operation

- Complete tempered discharge system without any solidification of heavy residues

- Sophisticated control cabinet for easy handling with CE and UL approval

- All heating/cooling circuits with maximized diameter and minimized length for optimized heat transfer

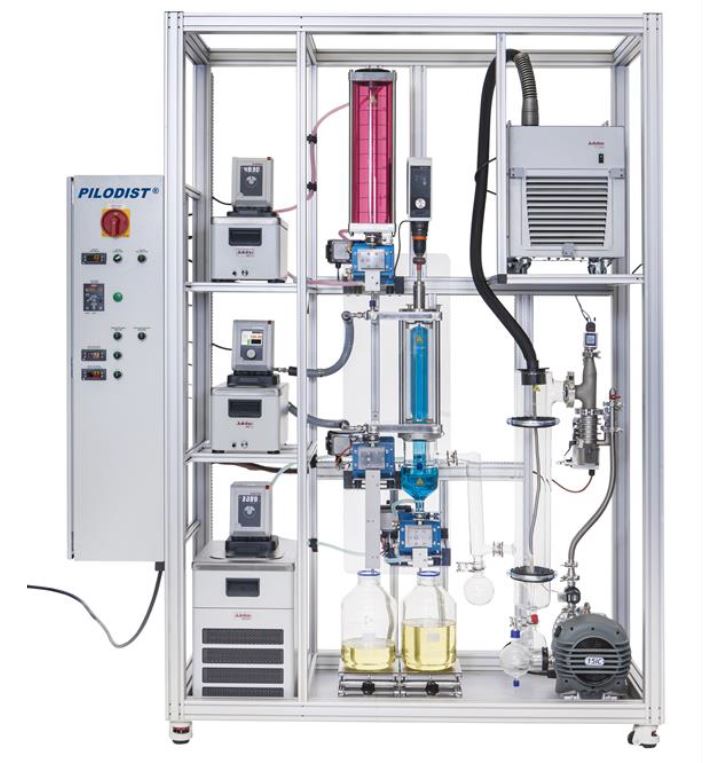

The SP1000CC is equipped with our unique and patent pending HYBRID-evaporator which combines all positive aspects of glass and stainless steel in one instrument. It is reliable and solid like stainless steel, but with the full visibility of a glass still.

Due to its complete heated inlet and outlet lines in combination with our tempered feed- and discharge pumps, melting points >150°C can be easily handled.

The sophisticated vacuum system is able to handle incondensable volatiles with its dry running chemical resistant scroll pump as well as the air cooled diffusion pump can reach a system pressure down to 0.00001mbar.

Due to the fully vacuum tight feed and discharge system there is no limitation in the charge or receiver vessel size and the system can run up to 24/7 operation without any interruption in the vacuum process and a throughput up to 7l/h.

Technical Data

- Operating temperature : up to 200°C (250…350°C optional)

- Final pressure : down to 10-5 mbar (optional)

- Feed range : approx. 1000-7000 ml/h, dep. on application

- Evaporator surface : 1000 cm2, short path

- Evaporator : borosilicate glass/stainless steel 316

- Feed vessel : 5000 ml, graduated, refillable

- Product receivers : variable (2x 5000ml included)

- Speed range of stirrer : 30…1000 rpm

- Dimensions (w x h x d) : 1750 x 2280 x 820 mm

- Electrical Supply : 230/400V 25A 3L+N+PE (50Hz or 60Hz available)