Kirjeldus

- Measurement range of 0.001-100%

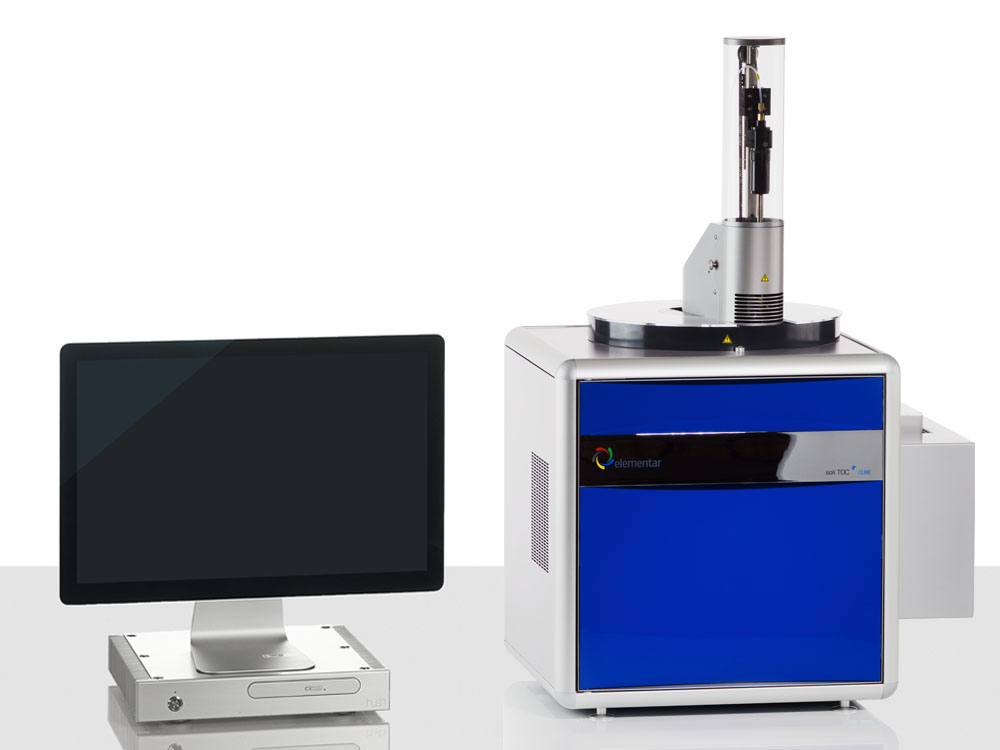

- Fully automated analysis with89 position autosampler

- Temperature programming withfast heating rates

- Optional carrier gas switching for better separation of ROC and TIC

- Option to determine nitrogen simultaneously

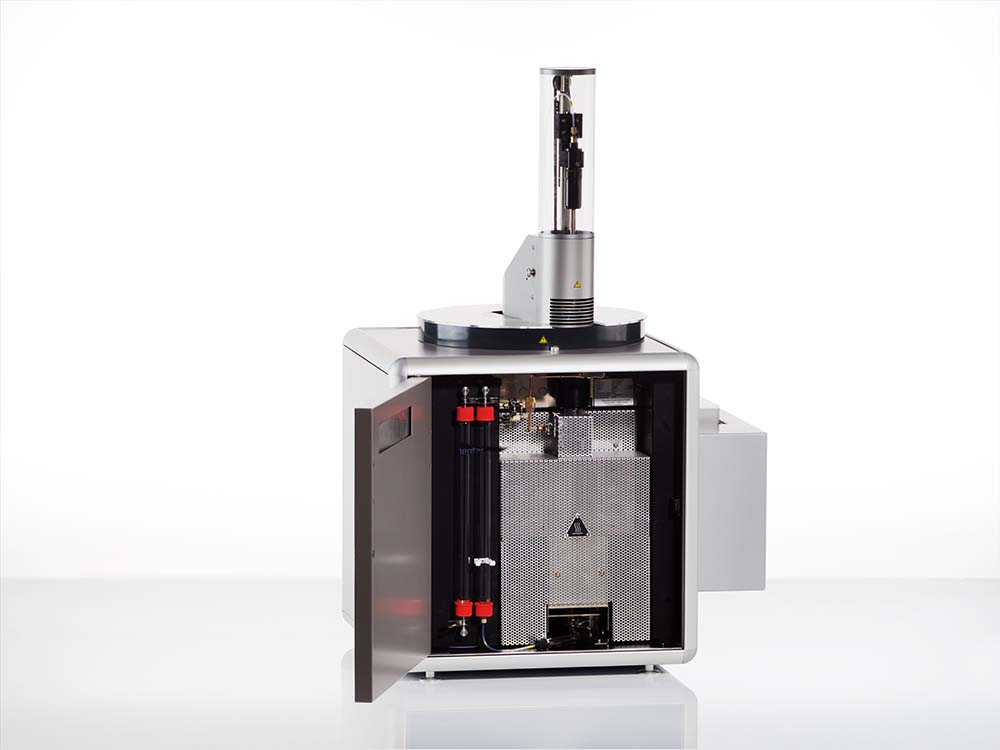

- Advanced crucible technology with automatic ash removal

- Conforms to new (DIN 19539) aswell as old (DIN 15936) standardsfor TOC determination in solid

Unmatched analytical performance

In temperature programming, a precise, adjustable temperature is required for reproducible measurements. Thus in the soli TOC cube, the temperature is measured where it matters, directly at the crucible. This eliminates all possible thermal interferences. Additionally, the use of a post-combustion catalyst ensures that even samples with a high carbon content are quantitatively oxidized and achieve equally high measurement quality

Simplified sample preparation

With the soli TOC cube, larger samples on the order of grams can be reliably analyzed: just weigh the solid samples in the reusable crucibles, place them on the autosampler, and start the sequence. This makes the soli TOC cube the perfect instrument for the precise analysis of inhomogeneous samples. Measurement of TOC according to DIN 15936 is also remarkably simple. The sample is acidified directly in the ceramic crucible and after drying delivered immediately to the instrument – simple, fast, and reliable.

Innovative gas switching

The separation of ROC and TIC can be improved by the use of an inert carrier gas. After the 400 °C temperature step, the carrier gas is switched from oxygen to nitrogen and the sample is directly pyrolyzed at 900 °C. Under these conditions, the ROC remains in the sample container while the TIC is converted to CO2. After the TIC is determined, the system is given oxygen again, whereby the ROC is oxidized. In most cases, this technique results in a better separation of TIC and ROC