Description

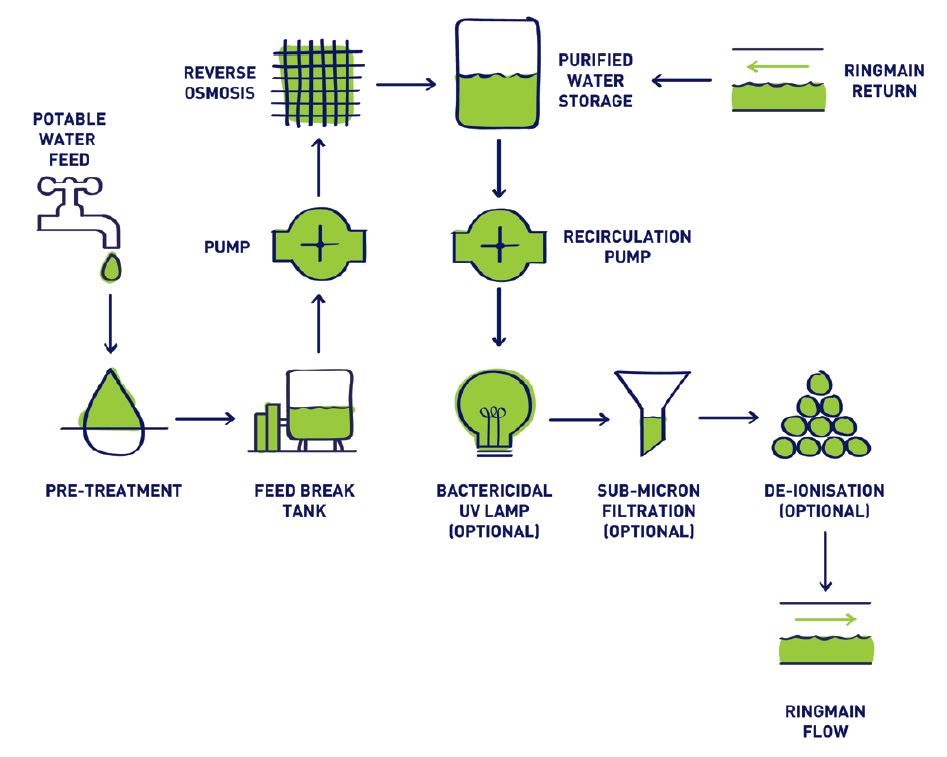

To provide higher grades of purified water the basic Integra L units can be supplemented by the addition of optional polishing packs comprising of stand-alone exchangeable cylinders. For applications requiring high quality water with enhanced bacterial specification, UV disinfection and 0.2μm filtration is available in an optional BIO pack.

- Single compact unit which purifies, stores and distributes lab water

- Produces up to 600 l/hr

- Provides ASTM Type I, II or III water and BS EN ISO grade 1,2 or 3 water

- Utilises reverse osmosis technology, in conjunction with activated carbon and particulate filtration as part of the first stage of purification

- Integrated data logging for performance traceability equipped as standard

- Delivered factory tested for ease of installation

- LCD touch screen display for ease of operation

| Treated Water Specification | |

| Conductivity | < 30μs/cm* |

| Bacteria | > 99% rejection** |

| Organics – TOC (ppb) | < 50*** |

| Particles | 0.2μm** |

| Endotoxins | 0.25EU/ml** |

* For enhanced inorganic and organic quality the unit can be fitted with either 10,15 or 18MΩ.cm polishing deionisers packs.

** Optional ‘BioPack’ will provide purified water with a total viable count of <1cfu/ml, endotoxin level <0.25EU/ml and particles <0.2μm

*** Typical level, depends on feedwater

| Installation Requirements | |

| Power | Single Phase, 230V, +/- 10%, 50 Hz |

| Feedwater | Potable* |

| Maximum TDS (ppm) | 1000 |

| Minimum inlet pressure – psi (bar) | 15 (1) |

| Maximum inlet pressure – psi (bar) | 90 (6.2) |

| Feedwater temperature | 1-35oC |

| Flowrate | – |

| Free chlorine | Must be dechlorinated |

* Softened feed water required for 600 l/hr (Integra LS). Integra LH can operate on hard water up to 400ppm as CaCO3