Description

- Control of homogenization degree and efficiency regarding product specification

- Secure and adjust shelf life of products

- Save energy by controlling the homogenization performance of industrial homogenizers

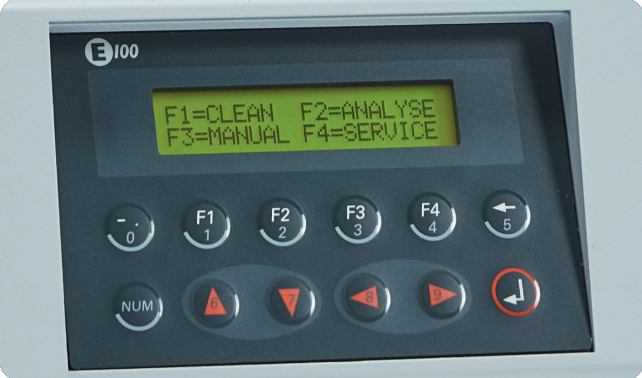

- Easy-to-use

- Results are independent of operator

- Fast measurement time

- Excellent cost/performance-ratio

Raw milk is inhomogeneous and contains relatively big globules which tend to aggregate leading to creaming effects. During the homogenization process, the particle size is adjusted to a required level. The GLOBULYSER is able to measure the mean size of fat globules in milk, liquid and powdered milk products within minutes and helps to efficiently operate dairy process plants.

Solutions for the Dairy industry

The GLOBULYSER has been developed for analyzing and determining the homogenizer efficiency for all long shelf life products, like UHT milk, condensed milk, pasteurized milk, a mixture of milk fat with vegetable fat, milk powder and cream powder.

Measurement Principle

The GLOBULYSER is based on measuring the intensity of transmitted and forward scattered light interacting with fat globules present in the sample cell. The forward scattering is directly depending on the size of the fat globules. The measured values are compared with the values of clean water and the difference is used to determine the mean size of the fat globules.