Description

High IP rating and stainless steel facilitate operation of the terminal in challenging working conditions (high humidity, dustiness). With these two characteristics the terminal meets high hygiene standards for food and pharmaceutical industries.

- The terminal’s housing and base are made of stainless steel. All the HY10 connectors are fed through glands, this along with water and dust proof housing guarantee high IP rating, IP68/69.

- 2-point terminal-base fixing system allows limit-free LCD tilt. Option of tilt angle adjustment improves ergonomics of use and optimises indication visibility.

- The terminal bracket ensures its stability during operation.

Rubber feet prevent unintentional device sliding. They cover openings through which the terminal can be permanently fixed either to a horizontal or vertical surface.

10.1” colour display of 1024×600 pixel resolution with a capacitive touchscreen

- Large, 10.1” backlit colour display guarantees easy-to-read information even in low light conditions. The indication can be read from a considerable distance, which increases your mobility.

- High resolution (1024×600) means high display readability providing crisper digits, symbols etc. Now you will not suffer from eye strain. The higher the resolution the greater comfort of use.

- The touchscreen stands for ease of operation, simply trust your intuition and start to operate the device. Now accessories such as mouse or keyboard are needless. Additional numeric keys and soft buttons provide maximum functionality.

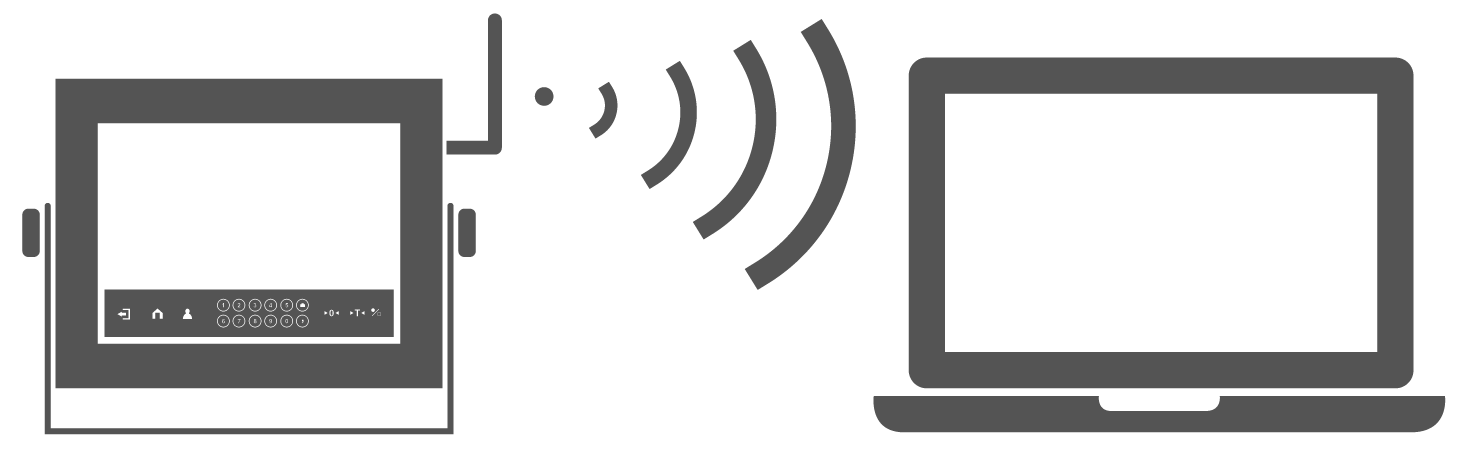

It is possible to set the HY10 terminal parameters remotely, this is done using ‘Parameters Editor 2.0’ software.

The parameters can also be set via the terminal. Use of ‘Parameters Editor 2.0’ software allows repeatable parameter setup.

Once you set all the parameters for a particular terminal, save them to a file in order to be able to copy them to terminals operating at twinlike workstations.

The set parameter configuration can be transferred either using a USB flash drive or a network. ‘Parameters Editor 2.0’ offers remote desktop option. With this solution we can carry out your terminal’s setup even if your company is located miles away from the service.

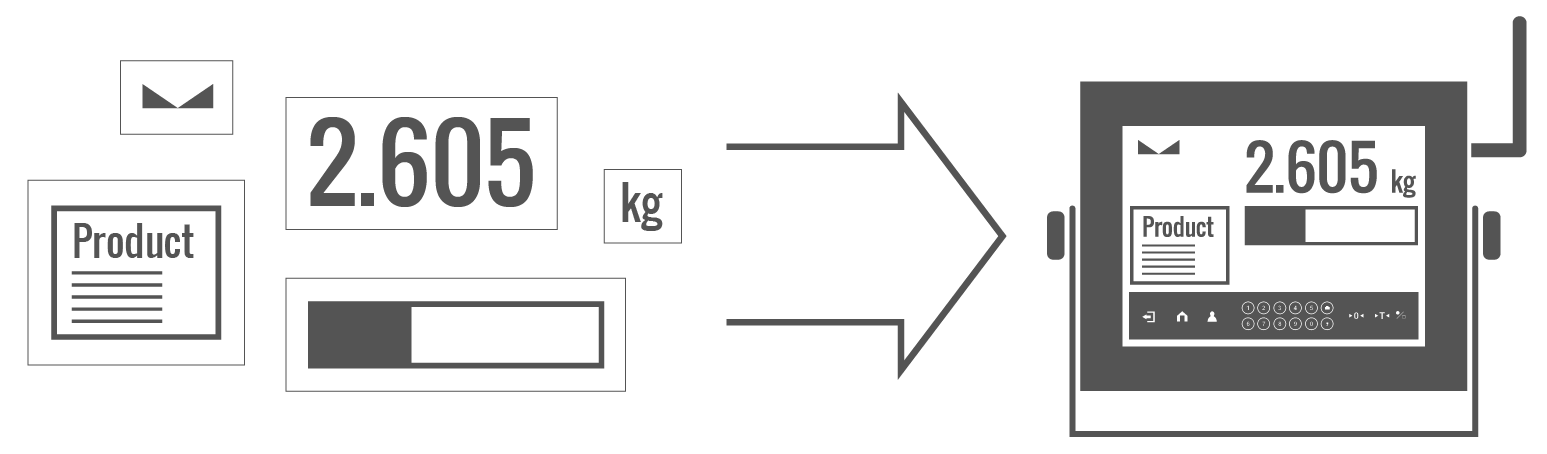

Customized screen layout, extensive functionality.

PUE HY10 terminal offers screen layout customization. You can display only those components that you find indispensable for your work.

You can make decision not only on what to add to your screen but also on the size of particular components. Self-designed screen layout makes your work easier, with this weighing is no longer a time-consuming process.

Ability to design labels for each terminal-performed process.

Labelling function, implemented into firmware, enables marking products with weight labels. This makes product identification fast and easy.

Using ‘Label Editor’, a dedicated software, you can design label which upon being sent to the scale is available for the operator in label database. The label can provide data such as date, batch number, mass, pictogram, Ean-13 code with weight value and product code.

Labelling enables:

- making Label Database in a terminal;

- assigning either a customized label to a particular product or a common label to a group of products;

- printing C labels (pallet) and CC labels (containers) providing total weight and quantity;

- automatically triggered printout of c labels.